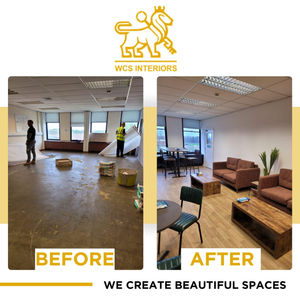

At WCS Interiors Ltd, based in Middlesbrough, we excel in delivering high-quality commercial fit-outs that improve the condition and functionality of your working environment in the UK. Our expertise in office fitting and refurbishment, glazed partitions, joinery services, and plastering ensures that every aspect of your project meets the highest standards. We understand the importance of a well-designed fit-out, which is why we focus on practical and aesthetically pleasing design, build, and streamlined project management.

Explore our case studies and completed projects to see our proven track record in creating effective and aesthetically pleasing commercial spaces. Ready to enhance your property? Contact WCS Interiors Ltd today to arrange an on-site meeting and discuss how we can bring your ideas to life.

CASE STUDY

CONSTRUCTION PROJECT CASE STUDY: JAMES COOK HOSPITAL – WARD 7

PROJECT OVERVIEW

Project Name – James Cook Hospital – Ward 7 Refurbishment

Location – James Cook Hospital, Middlesbrough

Client – South Tees NHS Foundation Trust/Hunter Electrical (Principal Contractor)

Project Type - Commercial/Healthcare

Start Date – July 2023

Completion Date – October 2023

Budget – Circa £160,000.00 (WCS scope)

PROJECT BACKGROUND

CLIENT'S OBJECTIVE

Full ward refurbishment is to be carried out in a live hospital environment. Contractors from all companies must work together to achieve a very particular and rigid schedule so that the ward can be commissioned at the correct time, as agreed with the hospital and trust. The Ward area is cleared for the project, but corridors and entryways are still used daily by hospital staff and patients, meaning material and waste have pre-planned routes and instructions to ensure minimal disruption and risk.

PROJECT SCOPE

WCS Interior Ltd’s scope of work was to build all new partition walls as per the proposed layout drawing, overboard all existing walls whilst installing pattresses for fixture and fitting installation. Door openings are created within all walls built, and necessary fire protection is provided as per wall type specification ensuring the ceiling carries the necessary fire rating in required areas. Supply and fit of all ceilings within the ward both suspended ceiling grid/tile and MF (metal frame) ceilings. Ceilings required different specifications throughout, such as non-corrosive grids in shower/wet rooms. Our scope of works also included a skim finish throughout the ward ready for decoration and the overall joinery package, including the installation of all FD30 and FD60 fire doors on site (single, double and leaf/half leaf door sets) and the installation of kitchens, beverage bays, corridor bumper rails and fitted furniture.

CHALLENGES

These projects always have the usual challenges of working with multiple contractors and companies in one area. Communication is a must, given that all trades need to work together to free up elements of work for each other and ensure the correct sequence is followed at all times to ensure the best use of time and to complete work efficiently and to the best possible standard. Because of the nature of the building, regular risk assessments and toolbox talks were a must to ensure that best practices are always followed, minimising risks and disruption to the rest of the building. Careful planning and multiple meetings prior to starting a project like this are paramount to cover all bases and be aware of any potential hazards and/or risks that can have a knock-on on effect the rest of the hospital systems and procedures. Again, with the remainder of the hospital open as usual, extra care had to be taken when delivering and removing items from the site, accepting large deliveries, access equipment etc.

PROJECT EXECUTION

PLANNING AND DESIGN

We have multiple meetings with the client prior to work commencing on-site. These will involve conference calls, team meetings and on-site meetings to discuss the work needed and the proposed schedules. During these stages, we can highlight any problems we foresee with the scheduling and designs and think of new or better ways to complete the scope of work to avoid disruption and minimise any potential delays. For example, during our on-site walkaround, we advised that over-boarding only chosen existing walls which were believed to be beyond repair and leaving slightly damaged ones for the plasterer to prepare would cause unnecessary delays and, in turn, overboarding all existing walls for the plasterer counteracted the amount of preparation work the plasterer needed to do to complete and would provide a far better finish for the client. Also, the pattress drawings provided were extremely intricate and covered most of the bed bay walls to house the multiple fixtures and fittings needed. We advised that for the amount of time taken on cutting out the mattresses and the amount of waste created, it would be more cost and time-effective to ply the full walls in question to which the trust agreed was the right thing to do. At this stage, we can also see how far up we have to go above ceiling height to ensure fire protection between rooms.

CONSTRUCTION PROCESS

Following the proposed layout drawing, we layout the walls in metal to segregate rooms, form new rooms and corridors etc. These will be plaster boarded at the thickness stated on the drawing and in the specification stated. Moisture Board to protect walls and ceilings from high humidity or in wet areas such as bathrooms, Soundbloc board for areas to reduce noise transmission, or Fireline plasterboard to increase fire resistance as part of a system. The new walls are built and boarded, and we overboard the existing walls which are staying in the necessary plasterboard to ensure a smooth finish and easy application for our plasterer. Sheets of ply will also be fitted in-between plasterboards for use as secure pattresses for fixtures and fittings as per the provided drawing. Certain rooms depending on the height of the soffit, will need fire protection to the highest point to prevent fires from spreading in the ceiling. Once the walls are built/overboarded and we fit our MF ceilings in the required areas our plasterers will skim the entirety of the ward block, which takes approximately 5-6 weeks. Following the plastering works, the joinery package will begin. We will receive a door schedule for the type of door which is going into the agreed opening. For these projects, the door sets tend to be pre-hung and ready for fitting, which allows for the regulatory gaps around the frame and from the floor to meet fire regulations. The joinery package also included fitting timber pattresses for bed bumper rails to be fixed, the installation of kitchens and beverage bay units following a CAD design and the installation of fitted furniture throughout the hospital supplied by the trust. For this project, the decoration was completed by another company, so we had to wait for the first coat to be applied to the walls above ceiling height (around 2.7m) and ensure that all mechanical, electrical and fire-stopping works were completed above the ceiling before we start our suspended grid systems. The systems were built in line with the client’s requirements, such as 600x600 ceiling tiles (specified as Rockfon Koral for maximum fire safety and sound absorption), 600x600 LED panel lights, and spacings created for 1200x600 radiant panels. We would work with the electrical team on-site to ensure their wiring was in the correct place, and ready for our ceilings to go in prior to tiling. As the tiles can gather dust and dirt quite easily, we tend to leave them as long as possible towards the end of the project before installation.

TEAM INVOLVEMENT

This project included;

Contractors

-

Ben Goddard (Joinery)

-

Michael Middleton (Joinery)

-

Daniel Shields (Ceilings/Dry lining)

-

Liam Walker (Ceilings/Dry Lining)

-

Martyn Whitehead (Ceilings/Dry Lining)

-

Sam Matthews (Ceilings/Dry Lining)

-

Ryan Marley (Ceilings/ Dry lining)

-

Andrew Atkinson (Plastering Sub-Contractor)

Management

-

Andrew Carter (Project Manager)

-

Jack Marsh (Project Manager)

-

Martyn Whitehead (Site Manager)

QUALITY CONTROL AND SAFETY MEASURES

Quality control is imperative to what we do because the majority of the work we are involved in is final finishes, such as the joinery on the show and the plaster finish to all walls and ceilings throughout. All of our work is showcased and seen which means the finished article has to be to the best possible standard. We ensure this with rigorous checks on-site at different stages to make sure that the levels we expect are being met. We will snag our team's work throughout the process so we can catch any potential issues early and make sure we are happy with the way things are progressing. We have also implemented sign-off sheets with the client so that they can have a walkaround at different stages and provide feedback if necessary. Safety protocols are of extreme importance on sites of this nature for a number of reasons. The live environment around the works, the different trades and companies encompassed in one project, the extensive works being carried out that have their own risks associated etc. We manage this by having a dedicated member of staff from each company monitor the safety of that particular company. Risk assessments and method statements are provided and updated in accordance with the changing environment as the works progress and toolbox talks are carried out every morning to discuss any potential issues that may arise within that day's scope of work. The communication between the trades and companies on site is paramount to creating a successful and safe environment. Although there are multiple measures in place to ensure safety is a priority, management will also attend weekly meetings to make sure the necessary precautions are being followed.

RESULTS

PROJECT OUTCOME

This project, along with the other ward refurbishments before it, was a huge success not only with the trust but the staff who would be using it and who visited prior to handover. The project was completed with no snags recorded in our elements which is a HUGE success given the amount of work involved within our scope. The project was handed over on time and on standard and has been since used as an example of how other wards are to be finished. Since the success of this project, Ward 5 has been awarded and is due to begin in September 2024.

KEY SUCCESSES

The biggest success for us as a business was handing over a project with no snags, which in our opinion, is simply unheard of. Even the biggest and best companies with the most intricate attention to detail will receive some snags and we believe snags are productive to recognise room for improvement. In this case, our consistent approach of monitoring the work and visiting periodically to ensure standards meant we could find problems early or get ahead of potential issues. There may have been snags earlier in the process, but because of our drive to improve and increase our standards, we had already rectified these prior to the handover. We completed our elements a couple of days ahead of schedule and to the budget/quotation provided. All in all, this project was a great success for WCS Interiors Ltd.

CLIENT TESTIMONIAL

“WCS Interiors Ltd completed multiple packages on the Ward 7 project. Dry lining, joinery, plastering and ceilings.

The contractors wore the correct PPE and were knowledgeable and helpful. They worked alongside other contractors on the job and worked with them to free up other areas for tradesmen in order for the job to progress. Overall, their punctuality was good, their level of work was good, they worked with any changes or alterations during the works, and they completed their packages on time and to standard”

Luke Marley – Hunter Electrical (Principal Contractor)

LESSONS LEARNED

CHALLENGES OVERCOME

As always, the construction industry will create challenges and obstacles during projects of this scale. Deliveries turning up late or with incorrect items, or something found on commencement of work that was unseen or unplanned prior. The main challenge with this project was the live environment that surrounds the refurbished area. Even though it was a heavy-duty project with lots of moving parts, outside of the doors of the ward are ongoing operations, hospital staff, patients and patrons, so you have to be aware of noise, risks, disruption and usually the delivery and removal of items through the hospital on and off the ward. Unfortunately, this is something you can’t avoid, but with the necessary planning in place you can make it as efficient as possible with the parameters you are working to. The biggest challenge we overcame was delivering this project on time with minimal disruption.

KEY TAKEAWAYS

As much as this was a successful project for WCS, we continue to look for ways to improve in quality, efficiency and speed. We have implemented daily report sheets for our Site Managers to report the progress of team member tasks on site to enhance efficiency. Project Managers attend more frequently to sign off completed areas with the client to ensure consistent quality control throughout and we also look to avoid any foreseeable project delays with regular site and office meetings.

CONCLUSION

PROJECT SIGNIFICANCE

These projects are always very important to us for a number of reasons. The main one is that we are extremely protective of the relationship we have built with this hospital over the many years of working together. They have provided us with wonderful opportunities to complete work in all different departments, which has allowed us to make a difference in areas that will influence and benefit the people of our town. A lot of our team are also very local to this hospital, so it’s always very personal to us to make sure we do a great job. Furthermore, projects of this calibre are excellent for us to show our skills and experience at what we deem is high-level commercial work. With large, challenging areas, live environments and working closely with multiple trades and companies, these projects push you very hard to ensure your organisation, quality, communication, documentation, and certification are all present and correct. We believe these projects put the professional pressure needed to bring out the best in us, from the office team to the on-site operatives.

FUTURE PROSPECTS

Briefly mention any future projects with the client or similar upcoming projects. Following completion, we have been awarded with many similar projects within healthcare facilities with the same scope of work. We have since completed Pirimal Healthcare Facility in Falkirk on behalf of Merit Health, Solihull Hospital Extension on behalf of Merit Health and other works within James Cook Hospital as well as the award of the new Ward 5 project due to start September 2024.

CONTACT INFORMATION

Project Manager: Jack Marsh, jack@wcs-ltd.co.uk, 07340 284055

Company Contact: Luke Marley - Hunter Electrical, lukehunterelect@aol.com, 07515 417157